In the pavilions engineered by the “Artesian spring” company new technology of washing and disinfection of reservoirs for storing potable water is carried out.

During the activity reservoirs are regularly washed and disinfected by means of a mobile CIP-washer using the car GAZ-3307. The mobile CIP-washer has a reservoir with detergent solution, a reservoir with clean water and a reservoir for collecting the used solution. To connect the reservoirs for storing water to the mobile CIP-washer there are ducts outside the pavilion which are connected to the cisterns of the car through a technological access door.

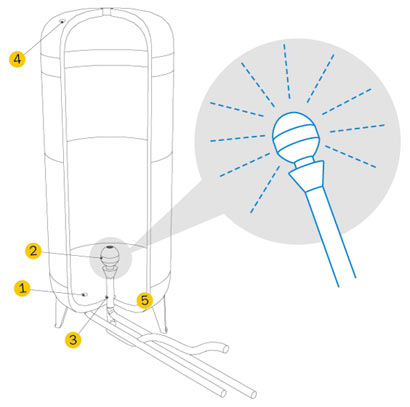

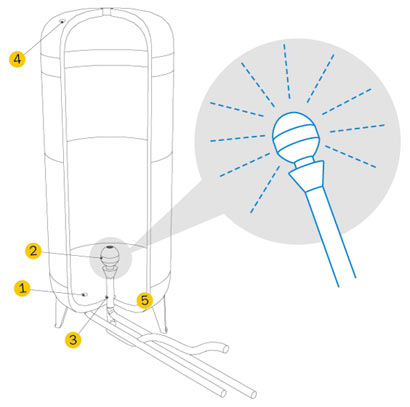

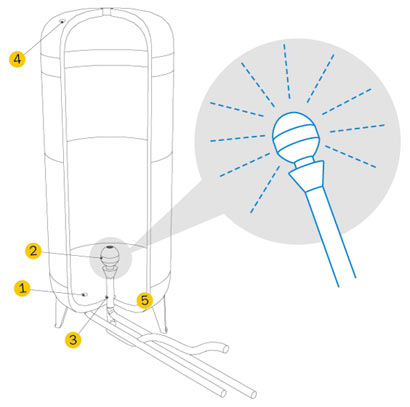

The washing process is carried out in the following way. The hose from the CIP-washer is connected to the washing head of the reservoir through a (1) special working aperture positioned in the bottom of the pavilion. Inside the reservoir a special detergent solution is sprayed under pressure that cleans the reservoir from possible salt deposition and disinfects it. The temperature of detergent solution is 70 degrees Celsius.

After that through the same (2) washing head water is sprayed under pressure that washes off the detergent solution. At the end of the washing process the solution with water is washed down to the (3) drain hole to which the hose of the CIP-washer is connected. Then all the solution is collected into the reservoir for the used solution located on the mobile CIP-washer. It is worth noting that the reservoirs for storing water have a solid (5) elliptic bottom. This structural feature does not allow even the gobbet of detergent solution and water to remain in reservoirs after the washing process.

In addition to washing, reservoirs in the pavilion are disinfected by ozone every time before they are filled up with water. It kills all possible microorganisms and goes out through a (4) vapor vent located in the top of the reservoir.